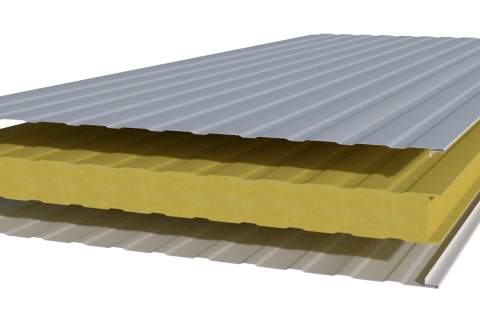

Briman DPPOLY group includes the products aimed at cold-room panel applications in high-or-low-pressure discontinuous lines.

Various formulations are avaliable with different blowing agents.

Materials included in this product group are designed by taking into consideration many essential points such as non-flammability, viscosity of the polyol formulation depending on manufacturing machine, reaction profile, and mechanical properties of the polyurethane foam.

Therefore the formulations are customer-specific, and finalised successfully thanks to the detailed studies performed in advance.

During manufacturing the temperature of the lower and upper sheets must be at least 35°C. Otherwise the adherence surface between foam and galvanised sheet becomes rigid and fragile than caused a weak adherence.

Therefore depending on thickness of the material, this product group should be kept in mould for 3 minutes for each cm thickness. Panels taken out of the mould should also be stored at room temperature for a while

BRİMAN DPPOLY group includes the materials of PIR/PUR 120-150 index and class B3 conforming to DIN 4102 standard.

BRİMAN DPPOLY group mostly compound of two-components which have the following properties:

- Prevention of potential defects on the sheet surface by discharging the air in the mould thanks to their low viscosity and ideal reaction profile,

- High performance against cold and hot temperature changes thanks to their high dimensional stability,

- High insulation performance,

- High production efficiency due to low viscosity ,

- Possibility of injection from single point.

- Less pressure on mould-release surfaces and easy removal from the mould without deformation thanks to their ideal formulation.